Tioga Downs Casino Resort Wastewater Upgrade

When the Owner of Tioga Downs won the rights to build out a full casino in 2016, he added a 160-room hotel and several restaurants, along with more gaming space. In addition to nearly doubling the daily flow rate, the Owner was faced with having to meet the new enhanced nutrient removal effluent (ENR) standards, required by the Chesapeake Bay Watershed Program. It would have cost nearly $2 million to meet these standards by upgrading the existing RBC system. However, the Engineer opted to research alternatives and turned to AquaPoint’s AquaCELL, Moving Bed Biofilm Reactors (MBBR) technology.

When the Owner of Tioga Downs won the rights to build out a full casino in 2016, he added a 160-room hotel and several restaurants, along with more gaming space. In addition to nearly doubling the daily flow rate, the Owner was faced with having to meet the new enhanced nutrient removal effluent (ENR) standards, required by the Chesapeake Bay Watershed Program. It would have cost nearly $2 million to meet these standards by upgrading the existing RBC system. However, the Engineer opted to research alternatives and turned to AquaPoint’s AquaCELL, Moving Bed Biofilm Reactors (MBBR) technology.

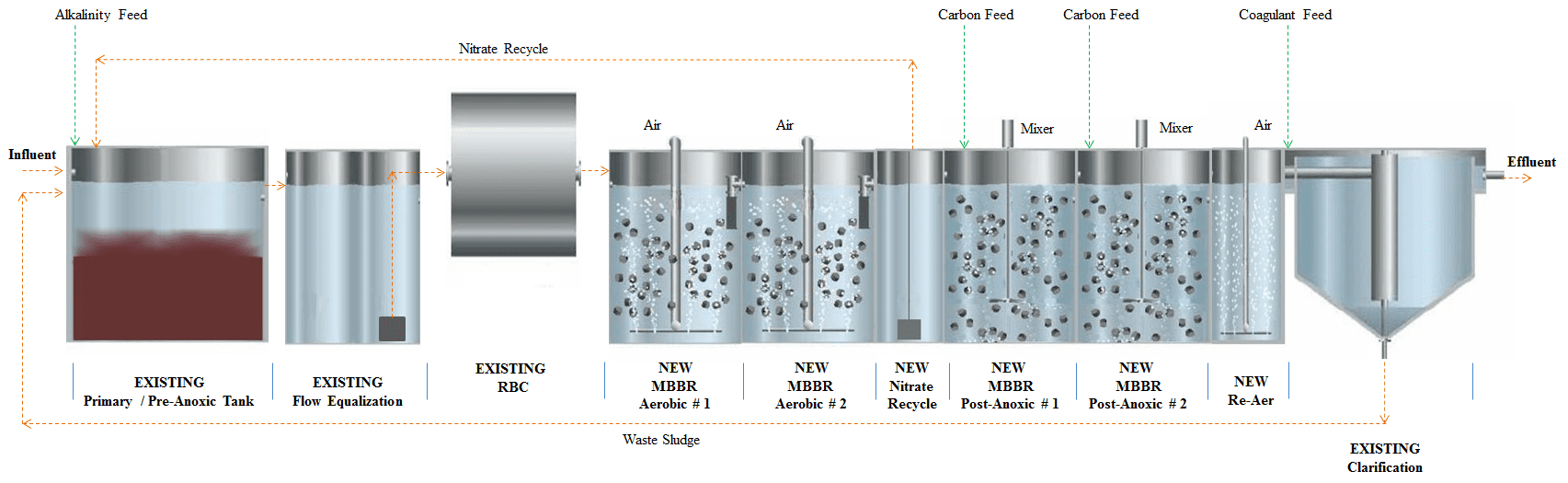

The challenge was to design a treatment system that would integrate with the existing RBC’s, as well as accommodate both the increased flow and higher effluent standards (see below table for influent characteristics and effluent standards). AquaPoint proposed a series of MBBR reactors, both aerobic and anoxic, to complete the carbonaceous, nitrification, and de-nitrification treatment needed to meet the new ENR standards. The process flow is primary settling –> flow equalization –> RBC –> AquaPoint MMBRs –> final clarifiers –> UV disinfection –> final discharge. In addition, carbon, coagulant & alkalinity are also supplemented to help treat the effluent to permit standards. Not only was this the best option for dealing with those standards as well as the issues created by the new hotel & restaurants, but it also proved to be incredibly economical and saved the owners close to $1 million dollars in capital costs. The system went into operation in the Fall of 2017.

Design Flow:

.125 MGD

Performance Requirements:

Influent: 250 BOD / 250 TSS / 65 TKN (mg/l) Effluent: 30 BOD / 30 TSS / 8 TN / 1 TP (mg/l)

BOD = Biochemical Oxygen Demand; TSS = Total Suspended Solids; TKN = Total Kjeldahl Nitrogen; TN = Total Nitrogen; TP = Total Phosphorous

*The above diagram shows basic process design, however the full system actually incorporates a dual train system where flow is split between two primary/flow EQ/RBCs into a single MBBR tank and then split again into final clarifiers and disinfection units.