Lawson’s Finest Liquids & AquaPoint

Not pictured: incredible tasting beer.

A few years back one of the Vermont’s most popular breweries decided to expand with a taproom and large brewing facility. The story of Sean Lawson and his growth in the beer industry is quite well known. What is largely unknown to most is some of the challenges they faced relating to the wastewater the brewery would generate. The Lawsons team decided to tie the tap room directly into the Waitsfield municipal treatment system. However, they could not do the same with the brewery wastewater primarily because the daily design flow of 6,000 gpd exceeded the available capacity. On top of that, brewery wastewater is extremely high strength so Lawson’s needed a partner that could provide that level of treatment – all while working within a small footprint and trying to keep capital costs down. They opted to partner with AquaPoint to work on a solution.

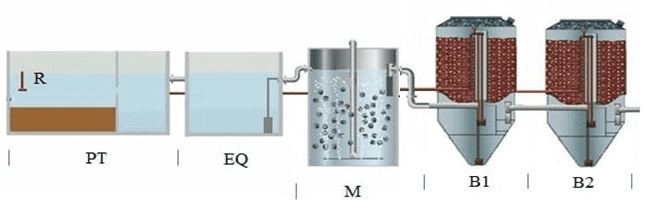

AquaPoint worked with both Lawsons & the engineering firm, in this case Weston & Sampson, and eventually settled on a Bioclere-OH hybrid system. For a full, detailed explanation on our Bioclere-OH click here. Simply put it is a two-stage treatment process that combines our AquaCELL MBBR process with our Bioclere high rate trickling filters. As is typical, AquaPoint designed the below system specifically to Lawsons’ needs. In addition to factoring in limited area and budget concerns as mentioned above, storage capacity and flow equalization were also major project drivers. Since no brewing takes place on weekends, the solution was to provide sufficient storage to allow the flow to be equalized, treated, and discharged over 7 days/week to keep the flow within the downstream treatment plant capacity.

The above diagram represents the following system flow: Primary Settling –> Equalization –> Aerobic MBBR –> (2) 24/12-1600 bioclere units in series. Also included in the system but not shown above are (3) chemical feed systems. These chemical feeds assist in both pH control and providing key nutrients typically not found in brewery wastewater that help promote cell growth. Finally, after the effluent passes through the Biocleres it enters into a lift station where it is discharged to the municipal system.

As you can see from the July/August influent & effluent numbers, the system is performing almost as well as the beer tastes!

| Avg. Influent BOD | Avg. Effluent BOD | Avg. Influent TSS | Avg. Effluent TSS | |

| July 2019 | 2,234 | 29.2 | 955.8 | 37.8 |

| August 2019 | 2,300 | 27.2 | 236.5 | 44 |

*Notes – 1. All figures shown in mg/l. 2. System was designed with following parameters: Average influent of 4,000 mg/l BOD & 1,000 mg/l TSS; effluent requirements of <250 mg/l on both BOD & TSS.

For more info on AquaPoint and breweries, head on over to this page!