AquaPoint & Aqua America Collaboration

Aqua America, a national wastewater utility company that services around three million people throughout the United States, faced some real challenges in early 2017 with a system they owned in the Beau Rivage community of Wilmington, North Carolina. Not only had the existing plant become obsolete, but in addition there was substantially increased daily flow as well as mandated regulatory increased on effluent limits. On top of that, as the coordinator for Aqua America said from the start, “We need the new plant operational within 1 year (from Spring 2017), and you have a postage size land allocation to fit the plant. Furthermore, we need you to deliver the system in (2) phases of parallel treatment trains since we cannot stop the treatment & processing of wastewater for even one day.” A very daunting challenge that they turned to AquaPoint to help them overcome.

Factoring in all the major project drivers – phased system trains, small footprint, increased effluent standards – AquaPoint opted for its AquaFAS process. As our website explains, “AquaFASTM is an integrated fixed-film activated sludge (IFAS) treatment process in which our MBBR biofilm carrier technology is incorporated with conventional suspended growth activated sludge…it achieves high levels of performance in small footprints while reducing the impact of solids loading on the clarification process. AquaFASTM is an ideal low-cost retrofit solution for conventional activated sludge systems that are at or beyond capacity…” (For a more detailed explanation of how our AquaFAS system works, check out this link).

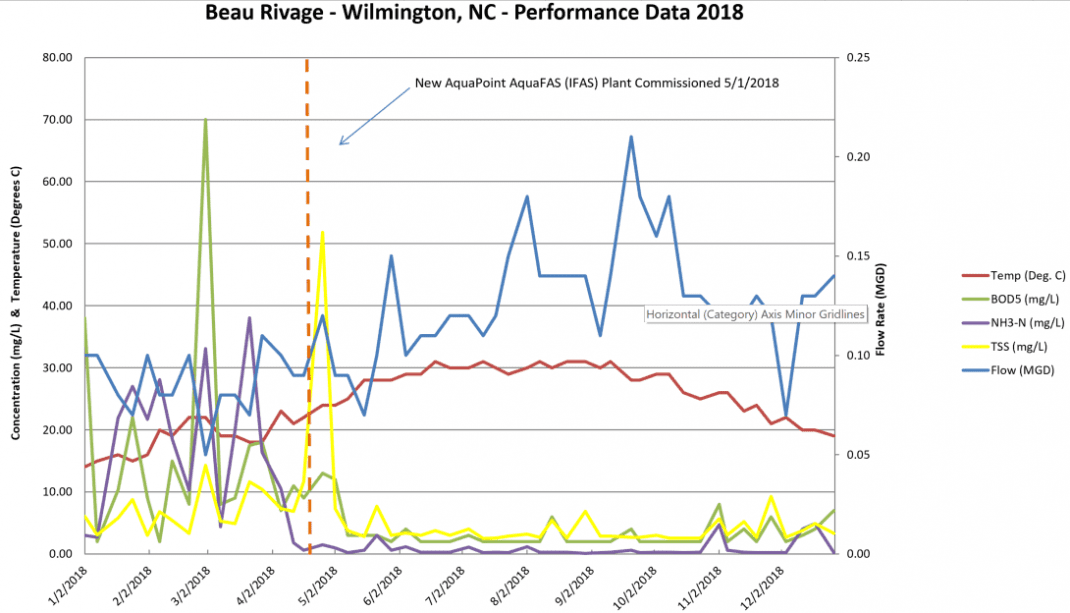

Fabricated in epoxy coated carbon steel tanks, AquaPoint was able to develop, install, and commission a dual train AquaFAS treatment system that went online in May 2018. Furthermore, AquaPoint delivered the system on the specified footprint as well as in phases so Aqua America could continue its wastewater treatment as requested. Clearly, based on the performance standards and chart below, you can see just how effective this system has been!

Performance Requirements:

Influent: 250 BOD / 250 TSS / 50 TKN (mg/l)

Effluent: 5 BOD / 5 TSS / 2 NH3 (mg/l)