AquaFAS™

Product Description

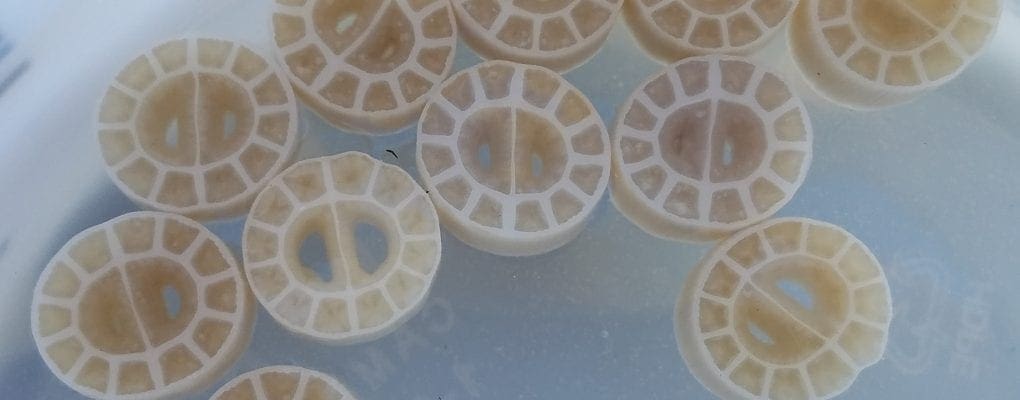

AquaFASTM is an integrated fixed-film activated sludge (IFAS) treatment process in which our MBBR biofilm carrier technology is incorporated with conventional suspended growth activated sludge. The hybrid process enhances volumetric productivity without increasing mixed liquor suspended solids (MLSS) concentrations. In doing so, it achieves high levels of performance in small footprints while reducing the impact of solids loading on the clarification process. AquaFASTM is an ideal low-cost retrofit solution for conventional activated sludge systems that are at or beyond capacity. Its small footprint and high-performance nitrification/denitrification capability also make it well suited for new construction applications.

Process Advantages

Enhances the Conventional Activated Sludge Process

The AquaFASTM (IFAS) process will operate just like an activated sludge process but with improved:

- Response to shock loading or toxic shock

- Cold temperature performance, especially for nitrification

- Resistance to filamentous overgrowth and sludge bulking

- Sludge settling characteristics

- Oxygen transfer efficiency (biofilm carriers serve as a shearing device)

- Retention of nitrifying organisms (reside on biofilm carriers)

- Total nitrogen removal

Increase Existing Plant Capacity & Performance

In most cases, it is possible to double the hydraulic capacity of your existing activated sludge reactor(s) or convert a secondary treatment plant to a nitrification/denitrification plant for < $1 per gallon treated with an IFAS upgrade.

Superior Nitrification & Denitrification

The IFAS process is specifically designed to enhance nitrification and denitrification. The biofilm carrier surface area provides an ideal environment for autotrophic organisms that are the backbone of the nitrification and denitrification process.

Reduced Clarifier Loading

By achieving a high-density population of fixed-film bacteria within the activated sludge process, mixed liquor (MLSS) levels are lower in relation to treatment productivity; clarifier performance is optimized by reducing the solids load generated from the secondary biological process.

Features

- Treats flows from 0.001 to 10 MGD

- Small footprints

- Cold climate nitrification/denitrification

- Capable of treating high strength and industrial wastewater

- Steel (carbon or stainless), fiberglass or concrete vessels

- Above ground or at grade installations

- Mobile Systems for temporary treatment

- Cost effective retrofits and upgrades

- Complete new build modular WWTPs

- UV resistant HDPE biofilm carriers

- Long media life cycle (> 20 years)

- Fully Automated PLC Control Systems